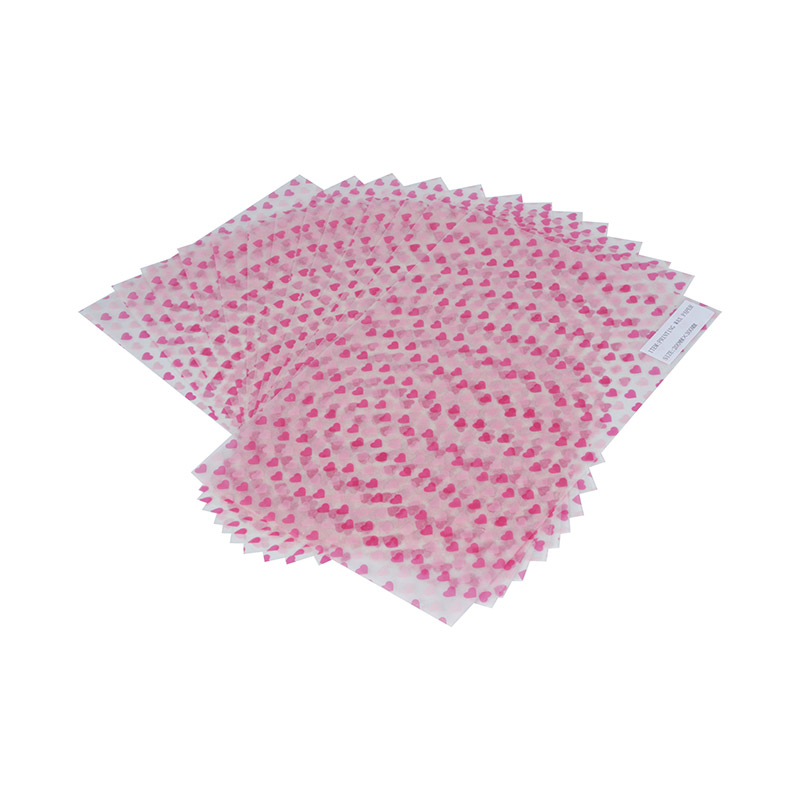

In the early days of candy production, wrappers were often basic and functional. Candies were typically sold in small quantities, often from bulk bins in stores. The packaging primarily served to protect the candy from contamination, preserve its freshness, and provide a basic level of information, such as the product's name and ingredients. At that time, materials like wax paper, foil, or cellophane were commonly used to wrap individual candies, and the designs were minimal, focusing mainly on practicality rather than aesthetics.

As the candy industry grew and manufacturers began to produce mass quantities of sweets, the role of packaging became more important. Candy wrappers began to take on new functions, such as advertising the brand and differentiating products in a crowded market. Companies realized that a well-designed wrapper could help catch the consumer's eye, appeal to their emotions, and increase sales. The wrapper became a powerful marketing tool, conveying not only the quality of the product but also the personality of the brand.

The design of candy wrappers evolved significantly in the mid-20th century with the advent of color printing technologies and the increased availability of plastic materials. Bright colors, logos, and eye-catching graphics became standard on candy wrappers, helping to establish brand identity and make products more recognizable. This period also saw the rise of iconic candy brands, many of which still dominate the market today. Companies like Hershey, Mars, and Nestlé began to perfect the art of candy wrapper design, creating distinctive packaging that consumers could instantly identify.

As the candy industry continued to grow, the need for more specialized packaging materials emerged. Manufacturers began to focus on creating wrappers that were not only visually appealing but also practical in terms of protecting the candy. Advances in materials like aluminum foil and polyethylene allowed for better preservation of the candy's freshness and taste. These materials also helped extend the shelf life of products, which became increasingly important as global distribution networks expanded. Modern candy wrappers now provide a barrier to moisture, light, and air, ensuring that the candy remains fresh and flavorful throughout its journey from factory to consumer.

In recent years, sustainability has become a key consideration in the design of candy wrappers. With growing concerns about plastic pollution and the environmental impact of single-use packaging, many candy manufacturers have shifted toward using more eco-friendly materials. Companies are experimenting with biodegradable, compostable, and recyclable wrappers made from paper, plant-based plastics, or other sustainable materials. Some brands have even committed to reducing the amount of plastic in their packaging by adopting recyclable or reusable alternatives, responding to consumer demand for more environmentally conscious products.

The advent of smart packaging technologies has also begun to influence the design of candy wrappers. Some companies have incorporated QR codes or augmented reality (AR) elements into their packaging, allowing consumers to interact with the product in new ways. These innovations not only enhance the consumer experience but also provide manufacturers with valuable data about product engagement and consumer preferences.

Beyond marketing and sustainability, candy wrappers continue to serve a crucial function in maintaining hygiene and safety. In an age where food safety is a significant concern, wrappers protect consumers from potential contaminants and ensure that products are safely sealed. The candy wrapper serves as an indicator of freshness and quality, reassuring consumers that the candy inside is both safe and delicious.

English

English русский

русский